News

How To Fit Fixed Folding Van Ramps To Your Van

Our slip-resistant aluminium folding van ramps are a great way to make loading and unloading your van safer - and easier. Our van ramps are lightweight and durable, and can...

How To Fit Fixed Folding Van Ramps To Your Van

Our slip-resistant aluminium folding van ramps are a great way to make loading and unloading your van safer - and easier. Our van ramps are lightweight and durable, and can...

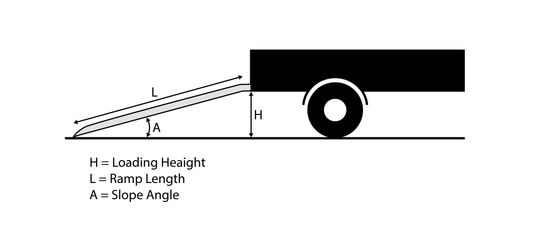

What size ramp do I need for my van?

Choosing the ideal ramp size can sometimes pose a bit of a challenge, but we've simplified the process to make it as effortless as possible for our customers. Our goal...

What size ramp do I need for my van?

Choosing the ideal ramp size can sometimes pose a bit of a challenge, but we've simplified the process to make it as effortless as possible for our customers. Our goal...

Transforming Accessibility: Alloy Ramps' Modula...

We were delighted to be asked to provide an access solution for a wheelchair user to be able to access their home with ease. We began the project by surveying the site...

Transforming Accessibility: Alloy Ramps' Modula...

We were delighted to be asked to provide an access solution for a wheelchair user to be able to access their home with ease. We began the project by surveying the site...

Alloy Ramps' Slip Test Results Are In!

All Alloy Ramps' ramps are manufactured with our industry-standard serrated, slip-resistant flooring, and to reassure ourselves as manufacturers as well as our customers, we recently arranged our ramps to be...

Alloy Ramps' Slip Test Results Are In!

All Alloy Ramps' ramps are manufactured with our industry-standard serrated, slip-resistant flooring, and to reassure ourselves as manufacturers as well as our customers, we recently arranged our ramps to be...

2023 For Alloy Ramps So Far...

We've had a fantastic first quarter of the year at Alloy Ramps, and so far, the second quarter looks to be even better!

2023 For Alloy Ramps So Far...

We've had a fantastic first quarter of the year at Alloy Ramps, and so far, the second quarter looks to be even better!

Lookback at The Commercial Vehicle Show 2023

The Commercial Vehicle Show this year was a great time. We got to reconnect with old friends and create new ones in the industry while meeting so many wonderful people...

Lookback at The Commercial Vehicle Show 2023

The Commercial Vehicle Show this year was a great time. We got to reconnect with old friends and create new ones in the industry while meeting so many wonderful people...